PCH Services

Validation and Manufacturing Services

Prior to production, PCH validates the performance specifications through rigorous reliability testing, and we manage all critical workflows to create efficient manufacturing lines.

Validation

To ensure a smooth transfer from product development to manufacturing, PCH conducts full Engineering Validation Testing (EVT), Design Validation Testing (DVT) and Production Validation Testing (PVT). At each phase of testing, we provide a risk-mitigation plan before moving forward.

Prototype units assembled with production intent manufacturing methods to prove out product reliability (drop, cycle life, etc.) and for evaluation of the production assembly line

Engineering Validation Test (EVT)

Prototype units assembled to evaluate final fit and cosmetic finishes, and submission for regulatory certification

Design Validation Test (DVT)

Salable finished goods assembled that meet the performance and reliability specifications when produced at scale

Production Validation Test (PVT)

Manufacturing Services

We refine the manufacturing process to optimize for cost improvements, quality requirements, reliability, volume and scalability

Confirm Capacity, Cycle Time and Line Yield

Capacity Management

Conduct necessary regulatory certifications

Regulatory and Compliance Management

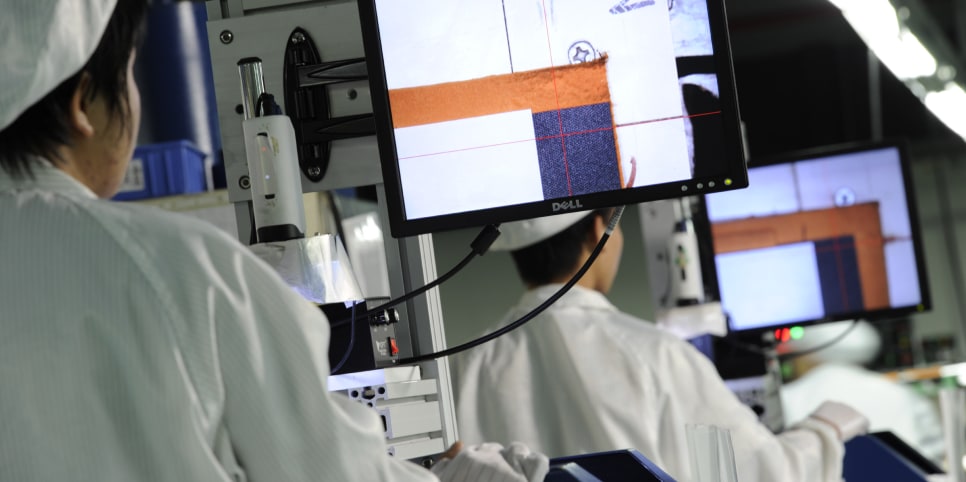

Make final adjustments and implement necessary quality control checkpoints

Quality Control

PCH utilizes a pull system to manufacture products on demand. We provide real-time data to our customers allowing them to oversee their on-hand inventory as well as inventory in their channel. This gives our customers control over the amount of product produced and when best to reorder.

Inventory Management

Next Service