PCH Services

Design and Development

At PCH we follow a rigorous engineering process that incorporates design-for-manufacturing early in our development, which enables us to bring innovative products to market faster and more reliably

Architect, Prototype & Test

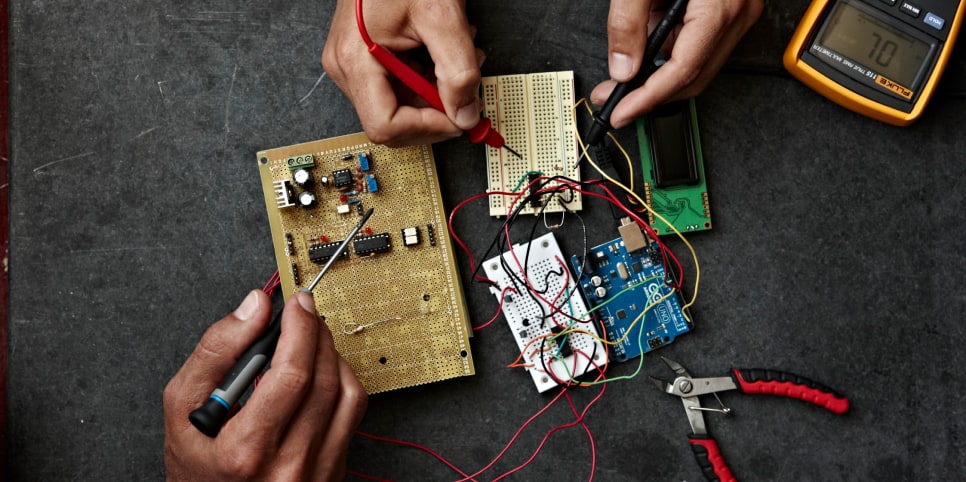

We follow rigorous engineering process that incorporates design-for-manufacturing early in our development

We architect complete solutions and validate and test key performance specifications at the sub-assembly level via breadboard prototypes. This process de-risks the integration phase.

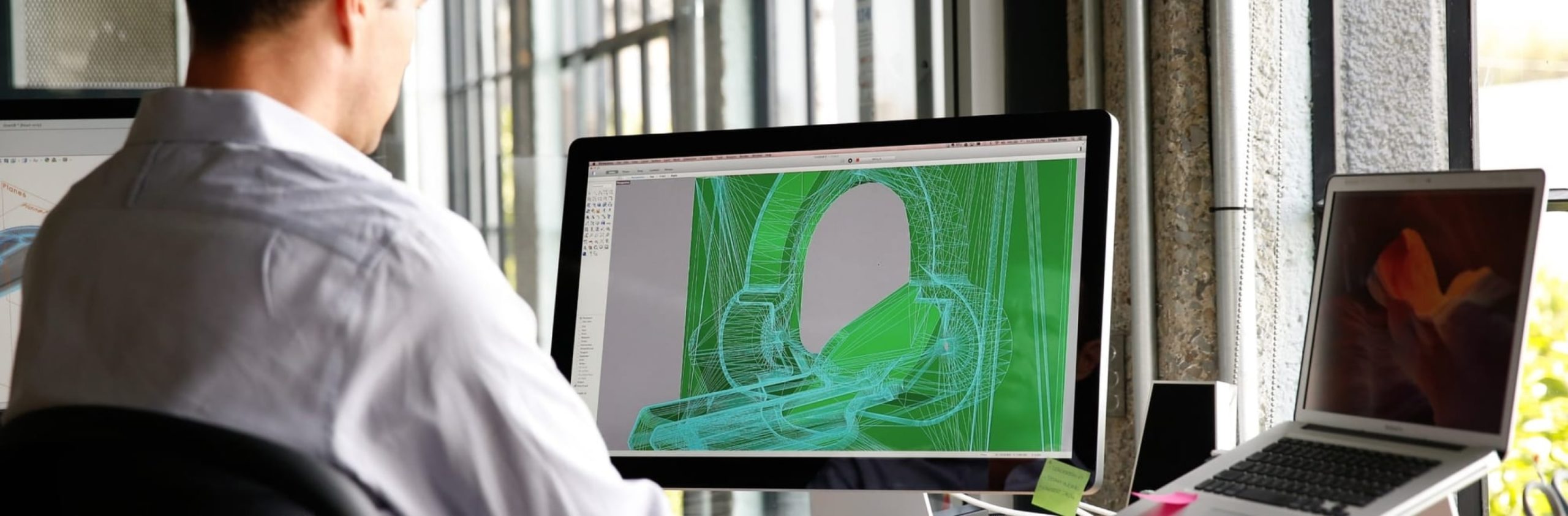

Architect

Working with our customers and their industrial design team, we reconcile design vision and cost with the detailed engineering design (using 3D mechanical CAD and volumetric studies, electrical schematics/layout, gestural UX models).

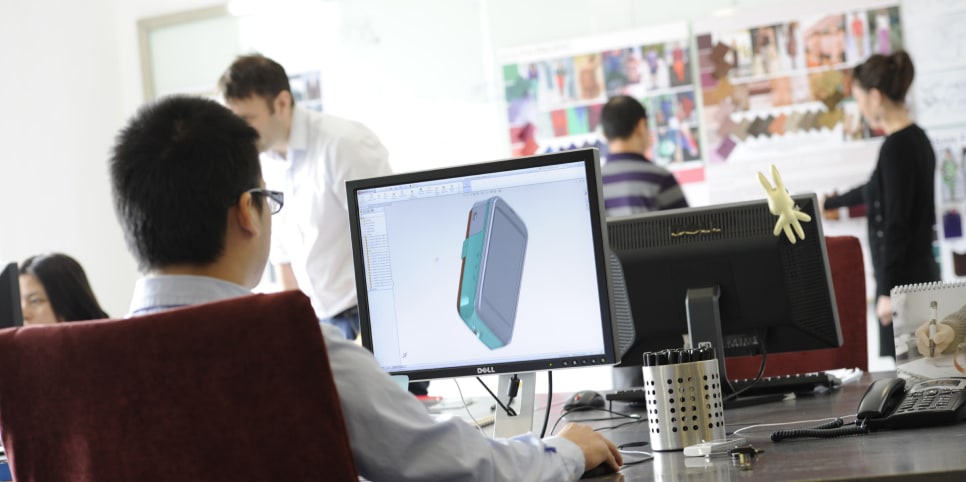

Reconcile

Produce looks-like and works-like prototypes based on production intent, detailed design, key components sourced from plan-of-record suppliers, and design for manufacturing.

Integrate

PCH uses a combination of rapid prototyping and production-intent manufacturing processes. We fabricate the mechanical parts and electrical components, and we source off-the-shelf solutions, where possible. We fabricate fully-featured prototypes to assess design intent, performance and manufacturability

Prototype

Next Service